Platforms

Vigel Platforms include High Speed Horizontal and Vertical Multi-Spindle Machining Centers. Different machine sizes allow to approach a wide range of workpieces in terms of dimensions and materials... Read more >

x-lines

A new Multi-spindle Vertical product line, a cost-effective solution combined with Vigel proven technology. The x-lines are configured with Twin-spindle.

Low space requirements ,... Read more >

MSHs

Vigel contribution to the lean manufacturing concept is represented by the MSHs Modules. MSHs Modules can be customized and used in various way as stand alone machines or part of...Read more >

- Progressive investment expenditure based on real volume requirements.

- Easy to retool and relocate in order to face the ongoing changes in the production market.

- Reduced cost of maintaining spare parts due to the modularity of the machines.

TRADITION IS OUR STRENGTH

For more than 30 years we have been developing and manufacturing Special Purpose Machines. CNC Rotary Transfers, CNC In-Line Transfers, Satellite Machines, CNC Lean Production Cells are some of the products installed all over the world. A strong tradition in the machine tool industry that marks the long road taken by Vigel over the decades and the primary role continuously played in a market which is currently considered difficult and highly competitive.

Download technical data |

|

Introducing the green part of Vigel

Energy through Energy.

Vigel Machining Centers recover the surplus kinetic energy during the deceleration and braking phases. The reconverted energy is re-entered in the network, instead of being dissipated through heat loss, accordingly reducing the energy consumption.

Sleep Mode to Minimize Energy Waste.

When no operations are in process, after 10 minutes (programmable time) a self-sufficient stand by mode gets activated. Machine power, hydraulic generator, coolant systems are temporarily shut down cutting energy consumption. Machine is ready and available for production.

LED Technology: Same Performance, less Consumption.

All the light sources on Vigel machines use LED technology in order to save energy.

Rationalized HP Calls.

A valve situated on the coolant tank, when it is not necessary to deliver HP coolant in the machine, discharges the coolant back to the tank, greatly reducing the pump motor absorption.

Stop and Go.

Vigel hydraulic power unit has a downstream accumulator in charge of entering the circuit with the proper oil pressure. When needed, the hydraulic power unit is used only to recover the pressure in the accumulator, avoiding overheating the oil and wasting energy.

Bio-Oil.

Lubrication Oil used in our equipments is biodegradable, leaving virtually no deposits and pollution to the environment.

Green Painting.

New Vigel environmental policies have led us to rethink the way we paint our products. Today all our equipments use eco-friendly painting. Powder coating and water-based paints are used instead of traditional petroleum-based solvents.

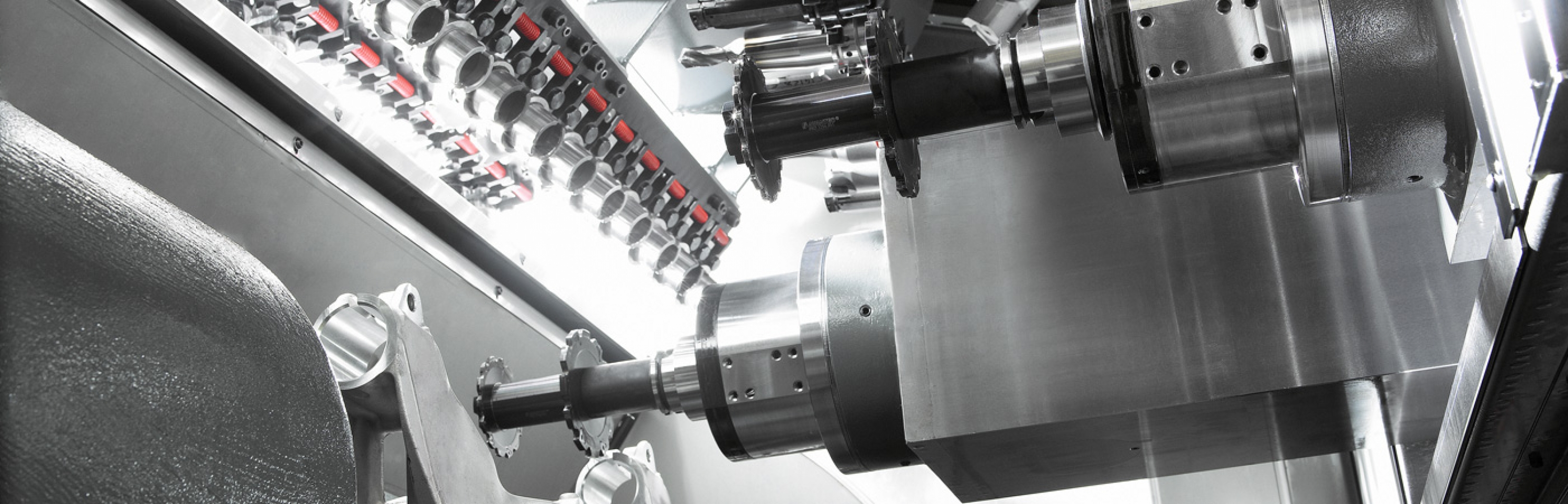

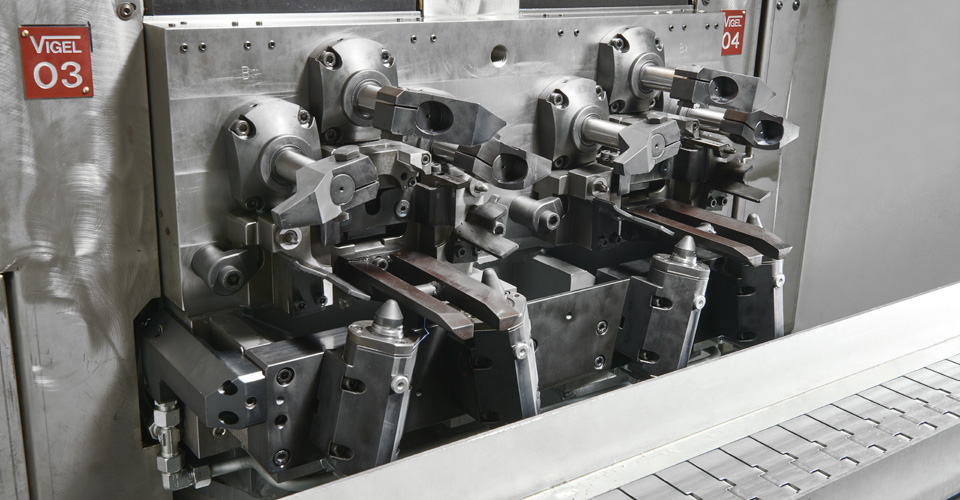

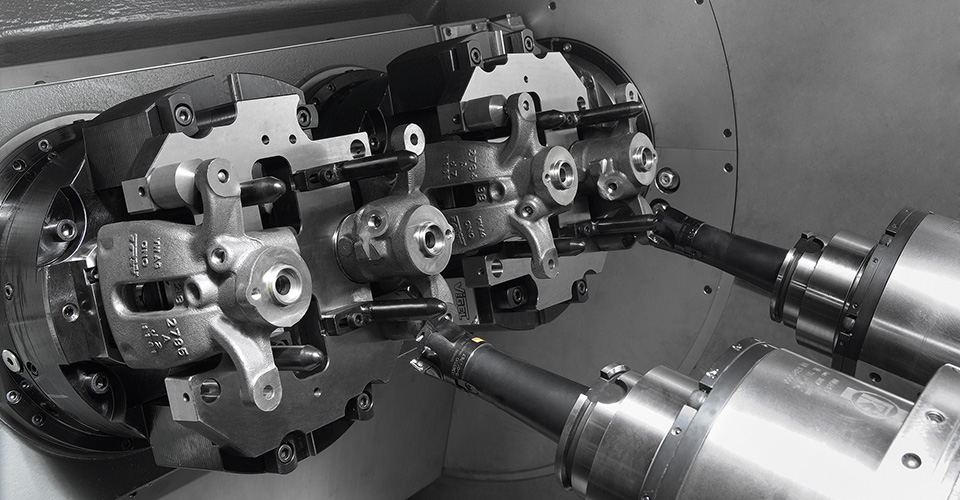

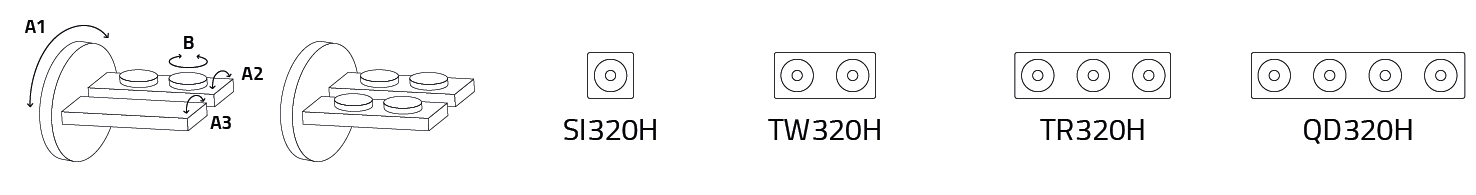

Platforms

Vigel Platforms include High Speed Horizontal and Vertical Multi-Spindle Machining Centers. Different machine sizes allow to approach a wide range of workpieces in terms of dimensions and materials. Different Spindle’s configurations from 2 up to 4, independent Z axes option, 4th & 5th axes capability, twin table or single table version, integrated automation, are some of the features that enable Vigel to define the right solution in terms of productivity, precision and reliability on each program.

MACHINE'S STRUCTURE

The need to respond quickly to market changes results in clear requirements for the automotive and sub-supplier industries: flexible use of machining systems, low space requirements, reductions in investment cost are all mandatory. Vigel Platforms Twin Table are based on modular concept. Due to the modularity variants and options available, customers can find the specific solution for their requirements reducing the variety of inventoried spare parts. The machine structure allows to approach an extremely wide range of workpieces in terms of dimensions and materials.

MULTI-SPINDLE TECHNOLOGY

Vigel Multispindle technologies is synonymous with lower investment cost per part and higher productivity. Vigel Platforms can be equipped from 2 up to 4 spindles based on production requirements. At identical production levels, multispindle machining centers require significantly less space than a comparable number of single spindle machining centers, shorter production time, less energy consumption and lower automation investment.

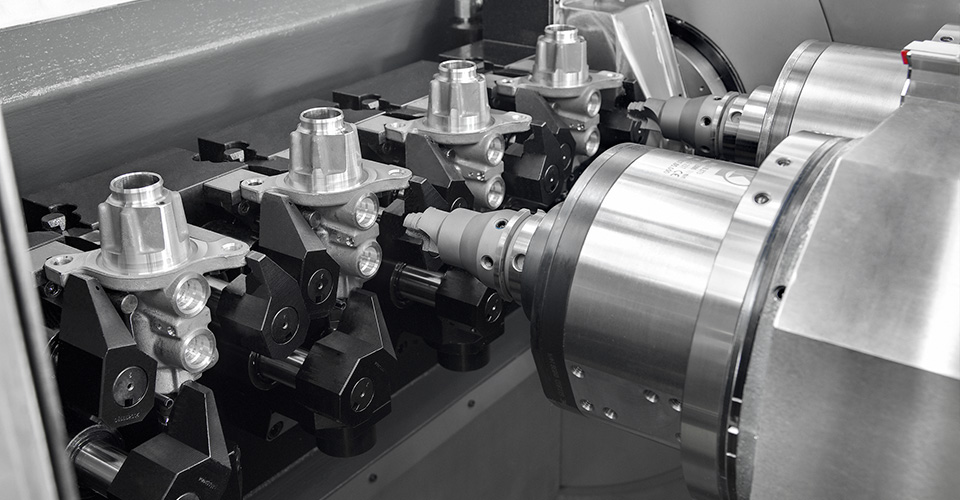

TWIN/SINGLE TABLE

Vigel Twin Table technologies enables the loading of the next work pieces while the previous parts are being machining. Beside the 0/180° pallet changer dedicated only to the Twin Table machine, all the Platforms have the same concepts and options available. Fixture plates are independent from the rest of the module, simplifying customer specific modifications and making it easy to retool the machine for new projects. The 4th and 5th axes options allow to finish the part in one clamping position improving workpiece quality and machine productivity.

TOOL MAGAZINE

All Vigel machining centers are equipped with drum-type magazine, designed and built by Vigel. The drum concept is extremely fast, precise and reliable. Different configurations allow to meet various needs in terms of capacity maintaining the same modular structure. Platform Twin Table, as all Vigel machining centers, uses direct tool change.

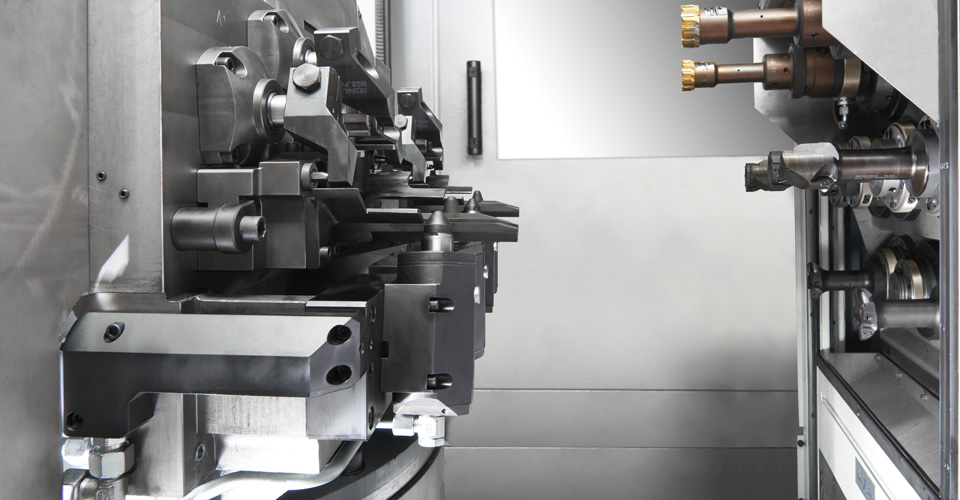

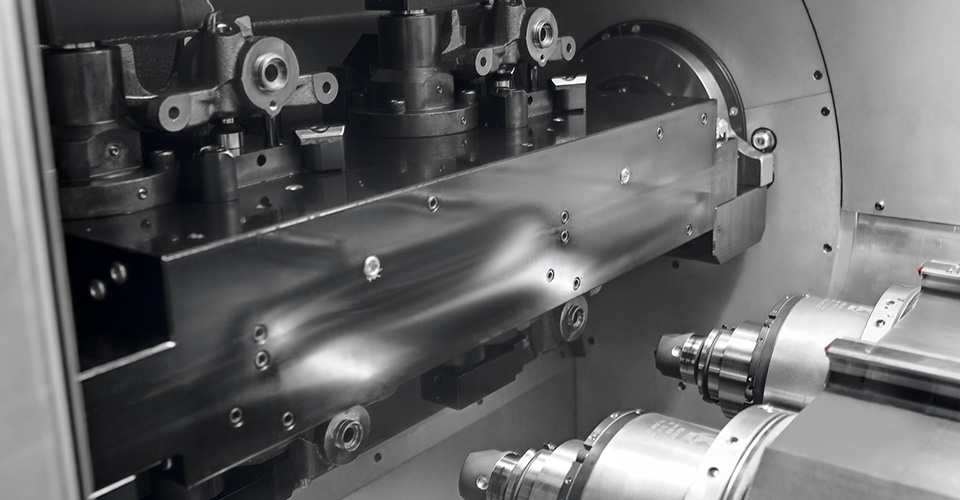

x-lines

A new Multi-spindle Vertical product line, a cost-effective solution combined with Vigel proven technology. The x-lines are configured with Twin- Spindle. Low space requirements , reductions in investment cost and proved quality standards are the guidelines that result in our new line of Vertical Machining Centers. Extremely compact, simple, with the productivity of a Twin-Spindle.

MACHINE'S STRUCTURE

All the x-lines are based on the same modular concept reducing the variety of spare parts among the different machine configurations. Twin Spindle Vertical Machining Centers with different spindle distance and the X-axis of the machine integrated on the swiveling table carrying fixtures and workpieces.

MULTI-SPINDLE TECHNOLOGY

The x-lines are configured with Twin Spindle Technology. Vigel spindle units, as for all Vigel products, are designed to obtain fast and cost-effective substitution reducing cost of maintenance and downtime.

SINGLE TABLE

The x-lines are equipped with one swiveling table, The 4th and 5th axis options allow to reduce the clamping positions, improving workpiece’s quality and machine’s productivity.

TOOL MAGAZINE

The x-lines are equipped with disk-type magazine, designed and built by Vigel. Different configurations and the chain-type option allow to meet various needs in terms of capacity. As all Vigel products also the x-lines use direct tool change.

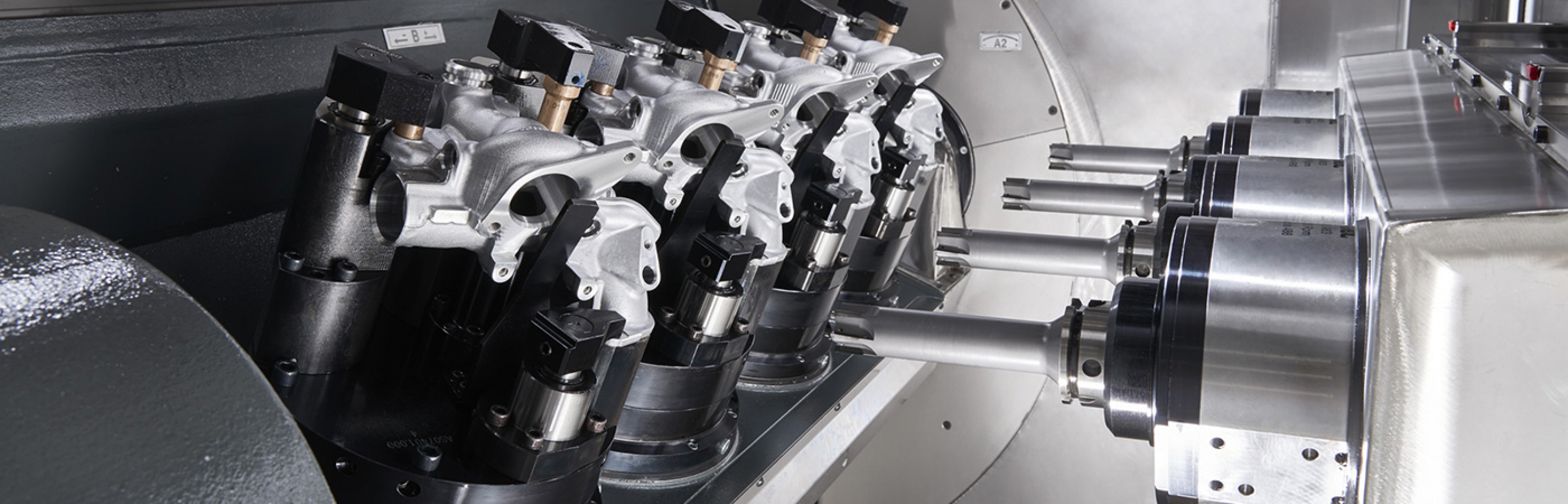

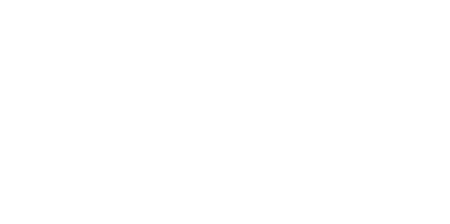

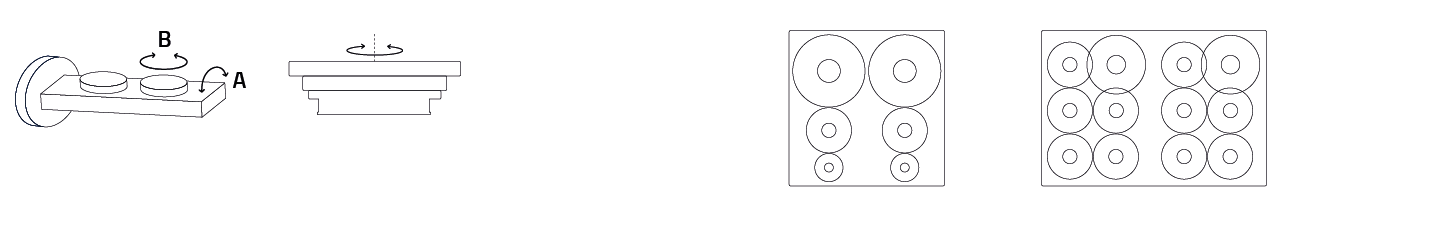

MSHs

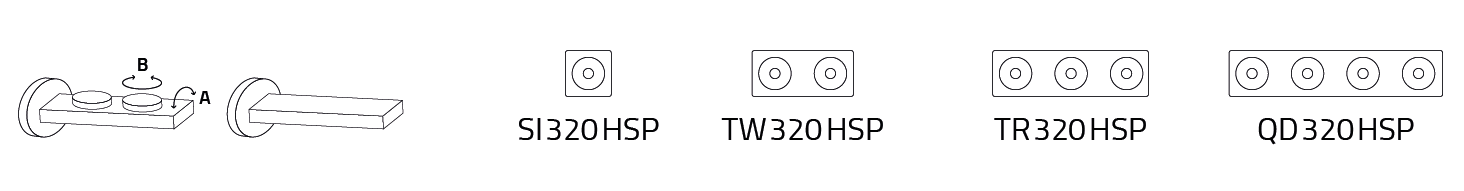

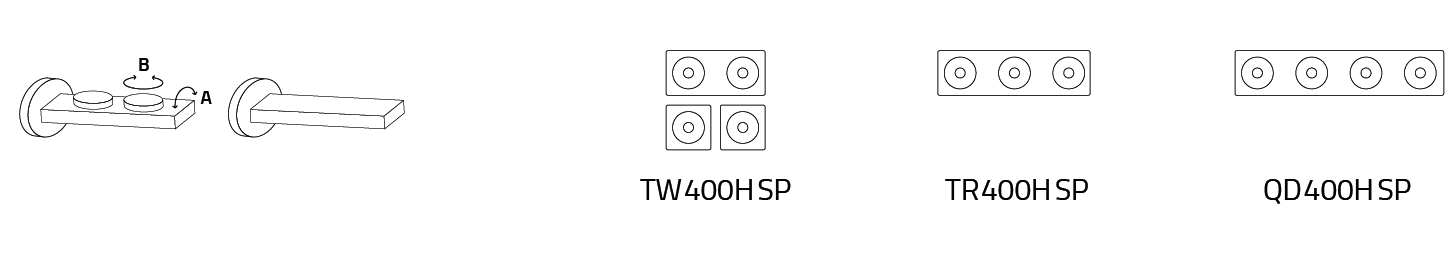

Vigel contribution to the lean manufacturing concept is represented by the MSHs Modules. MSHs Modules can be customized and used in various way as stand alone machines or part of flexible manufacturing cells, two different sized 500 & 630, from 2 up to 12 sequentially operating spindles, chip to chip time 1.5 sec. are some of the features that characterize the success of the MSHs lines over the years.

MODULE'S STRUCTURE

MSHs Modules can be customized to cope with a wide range of production requirements. MSHs Modules can be use as stand alone machines or link one with the others forming Production Cells which ensure smooth material flow and effective progressive process.

SPINDLE HEAD

Vigel MSHs are equipped with multi-spindle head, that can be configured starting from 2 up to 12 sequentially operating spindles. Chip to Chip time faster then any other tool change system. Spindles alternatives allow to machine a wide range of workpieces in a variety of materials.

WORKPIECE'S AREA

MSHs Modules can be equipped with 0°-180° rotary table allowing to load / unload during machine time or a single table carrying the 4th and 5th axes. The modules allow manual or automatic load / unload and various transfer systems are applicable to link the cells.

Download technical data |

|

Introducing the green part of Vigel

Energy through Energy.

Vigel Machining Centers recover the surplus kinetic energy during the deceleration and braking phases. The reconverted energy is re-entered in the network, instead of being dissipated through heat loss, accordingly reducing the energy consumption.

Sleep Mode to Minimize Energy Waste.

When no operations are in process, after 10 minutes (programmable time) a self-sufficient stand by mode gets activated. Machine power, hydraulic generator, coolant systems are temporarily shut down cutting energy consumption. Machine is ready and available for production.

LED Technology: Same Performance, less Consumption.

All the light sources on Vigel machines use LED technology in order to save energy.

Rationalized HP Calls.

A valve situated on the coolant tank, when it is not necessary to deliver HP coolant in the machine, discharges the coolant back to the tank, greatly reducing the pump motor absorption.

Stop and Go.

Vigel hydraulic power unit has a downstream accumulator in charge of entering the circuit with the proper oil pressure. When needed, the hydraulic power unit is used only to recover the pressure in the accumulator, avoiding overheating the oil and wasting energy.

Bio-Oil.

Lubrication Oil used in our equipments is biodegradable, leaving virtually no deposits and pollution to the environment.

Green Painting.

New Vigel environmental policies have led us to rethink the way we paint our products. Today all our equipments use eco-friendly painting. Powder coating and water-based paints are used instead of traditional petroleum-based solvents.

Download technical data |

|

Introducing the green part of Vigel

Energy through Energy.

Vigel Machining Centers recover the surplus kinetic energy during the deceleration and braking phases. The reconverted energy is re-entered in the network, instead of being dissipated through heat loss, accordingly reducing the energy consumption.

Sleep Mode to Minimize Energy Waste.

When no operations are in process, after 10 minutes (programmable time) a self-sufficient stand by mode gets activated. Machine power, hydraulic generator, coolant systems are temporarily shut down cutting energy consumption. Machine is ready and available for production.

LED Technology: Same Performance, less Consumption.

All the light sources on Vigel machines use LED technology in order to save energy.

Rationalized HP Calls.

A valve situated on the coolant tank, when it is not necessary to deliver HP coolant in the machine, discharges the coolant back to the tank, greatly reducing the pump motor absorption.

Stop and Go.

Vigel hydraulic power unit has a downstream accumulator in charge of entering the circuit with the proper oil pressure. When needed, the hydraulic power unit is used only to recover the pressure in the accumulator, avoiding overheating the oil and wasting energy.

Bio-Oil.

Lubrication Oil used in our equipments is biodegradable, leaving virtually no deposits and pollution to the environment.

Green Painting.

New Vigel environmental policies have led us to rethink the way we paint our products. Today all our equipments use eco-friendly painting. Powder coating and water-based paints are used instead of traditional petroleum-based solvents.

Download technical data |

|

Introducing the green part of Vigel

Energy through Energy.

Vigel Machining Centers recover the surplus kinetic energy during the deceleration and braking phases. The reconverted energy is re-entered in the network, instead of being dissipated through heat loss, accordingly reducing the energy consumption.

Sleep Mode to Minimize Energy Waste.

When no operations are in process, after 10 minutes (programmable time) a self-sufficient stand by mode gets activated. Machine power, hydraulic generator, coolant systems are temporarily shut down cutting energy consumption. Machine is ready and available for production.

LED Technology: Same Performance, less Consumption.

All the light sources on Vigel machines use LED technology in order to save energy.

Rationalized HP Calls.

A valve situated on the coolant tank, when it is not necessary to deliver HP coolant in the machine, discharges the coolant back to the tank, greatly reducing the pump motor absorption.

Stop and Go.

Vigel hydraulic power unit has a downstream accumulator in charge of entering the circuit with the proper oil pressure. When needed, the hydraulic power unit is used only to recover the pressure in the accumulator, avoiding overheating the oil and wasting energy.

Bio-Oil.

Lubrication Oil used in our equipments is biodegradable, leaving virtually no deposits and pollution to the environment.

Green Painting.

New Vigel environmental policies have led us to rethink the way we paint our products. Today all our equipments use eco-friendly painting. Powder coating and water-based paints are used instead of traditional petroleum-based solvents.

Download technical data |

|

Introducing the green part of Vigel

Energy through Energy.

Vigel Machining Centers recover the surplus kinetic energy during the deceleration and braking phases. The reconverted energy is re-entered in the network, instead of being dissipated through heat loss, accordingly reducing the energy consumption.

Sleep Mode to Minimize Energy Waste.

When no operations are in process, after 10 minutes (programmable time) a self-sufficient stand by mode gets activated. Machine power, hydraulic generator, coolant systems are temporarily shut down cutting energy consumption. Machine is ready and available for production.

LED Technology: Same Performance, less Consumption.

All the light sources on Vigel machines use LED technology in order to save energy.

Rationalized HP Calls.

A valve situated on the coolant tank, when it is not necessary to deliver HP coolant in the machine, discharges the coolant back to the tank, greatly reducing the pump motor absorption.

Stop and Go.

Vigel hydraulic power unit has a downstream accumulator in charge of entering the circuit with the proper oil pressure. When needed, the hydraulic power unit is used only to recover the pressure in the accumulator, avoiding overheating the oil and wasting energy.

Bio-Oil.

Lubrication Oil used in our equipments is biodegradable, leaving virtually no deposits and pollution to the environment.

Green Painting.

New Vigel environmental policies have led us to rethink the way we paint our products. Today all our equipments use eco-friendly painting. Powder coating and water-based paints are used instead of traditional petroleum-based solvents.

Highlights |

||

|

Vigel Range of Product : New Entry... TW 660H Lineare Twin Spindle Horizontal Machining Center |

|

ExpertiseAn extraordinary expertise established over decades, from standalone machines over complex integrated solutions, place Vigel among the most qualified and reliable supplier of Turnkey Solutions... Read more > |

ServiceSA strong Service infrastructure base guaranteed by experienced technicians operates next to our main markets of reference. All our sources are direct sources ensuring an effective problem solving... Read more > |